Ensure the reliability, safety, and longevity of your aerospace components with Wings Of Aero’s “Stress Analysis and Fatigue Testing” service. Our comprehensive approach involves detailed stress analysis and rigorous fatigue testing to guarantee that materials and structures meet the highest standards of performance and durability.

Key Features:

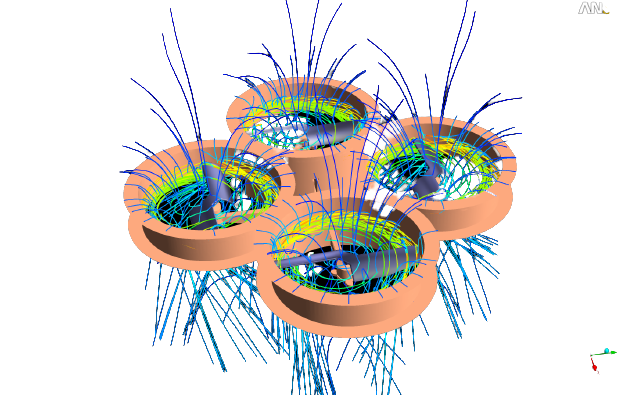

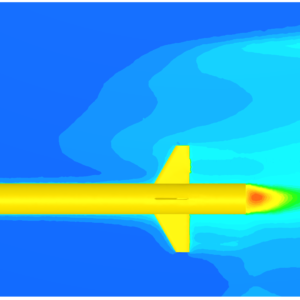

Comprehensive Stress Analysis: Perform detailed stress analysis on aerospace components to identify areas of potential failure and ensure structural integrity. Our analysis includes finite element analysis (FEA), stress concentration factors, and load distribution assessments.

Fatigue Life Prediction: Accurately predict the fatigue life of materials and components under cyclic loading conditions. Our fatigue life prediction models consider various factors such as stress levels, material properties, and environmental conditions.

Load Testing: Conduct extensive load testing to evaluate how components perform under different types of loading conditions, including static, dynamic, and impact loads. Our tests ensure that materials can withstand operational stresses.

Cyclic Loading Tests: Implement cyclic loading tests to simulate real-world operating conditions. Our tests help determine the endurance limit and fatigue strength of materials and components.

Crack Growth Analysis: Analyze crack initiation and propagation to understand the behavior of materials under stress. Our crack growth analysis helps in developing maintenance schedules and improving design for enhanced durability.

Environmental Influence Assessment: Evaluate the impact of environmental factors such as temperature, humidity, and corrosive environments on material performance. Our assessments ensure that components can withstand harsh operating conditions.

Non-Destructive Testing (NDT): Utilize non-destructive testing techniques to inspect components for internal and surface defects without causing damage. Our NDT methods include ultrasonic testing, radiographic testing, and magnetic particle inspection.

Stress Concentration Reduction: Identify and address stress concentration areas to enhance the overall strength and fatigue resistance of components. Our solutions include design modifications and material selection recommendations.

Compliance and Certification: Ensure that components meet relevant aerospace regulations and standards. We provide comprehensive documentation and support for compliance and certification processes.

Customized Solutions: Deliver tailored stress analysis and fatigue testing solutions to meet the specific needs of your aerospace projects. Whether for new designs, upgrades, or maintenance, our solutions align with your goals.

Expert Consultation: Leverage the expertise of our stress analysis and fatigue testing engineers. We offer ongoing support and expert advice throughout your project lifecycle, ensuring successful implementation and operation.

Applications:

- Aircraft structures and components

- Engine parts and systems

- Aerospace tooling and fixtures

- Unmanned aerial vehicles (UAVs)

- Spacecraft and satellites

- Retrofit and upgrade programs

Why Choose Wings Of Aero?

Wings Of Aero is dedicated to advancing aerospace engineering through innovative and reliable solutions. Our “Stress Analysis and Fatigue Testing” service combines cutting-edge technology with deep industry knowledge to deliver components that meet and exceed performance expectations. Trust us to provide solutions that enhance reliability, safety, and longevity.

Contact Us:

Discover how our “Stress Analysis and Fatigue Testing” service can optimize your aerospace projects. Contact Wings Of Aero today for a consultation and take the first step towards engineering excellence.

Ensure the reliability, safety, and longevity of your aerospace components with Wings Of Aero’s “Stress Analysis and Fatigue Testing” service. Our comprehensive approach involves detailed stress analysis and rigorous fatigue testing to guarantee that materials and structures meet the highest standards of performance and durability.

Key Features:

Comprehensive Stress Analysis: Perform detailed stress analysis on aerospace components to identify areas of potential failure and ensure structural integrity. Our analysis includes finite element analysis (FEA), stress concentration factors, and load distribution assessments.

Fatigue Life Prediction: Accurately predict the fatigue life of materials and components under cyclic loading conditions. Our fatigue life prediction models consider various factors such as stress levels, material properties, and environmental conditions.

Load Testing: Conduct extensive load testing to evaluate how components perform under different types of loading conditions, including static, dynamic, and impact loads. Our tests ensure that materials can withstand operational stresses.

Cyclic Loading Tests: Implement cyclic loading tests to simulate real-world operating conditions. Our tests help determine the endurance limit and fatigue strength of materials and components.

Crack Growth Analysis: Analyze crack initiation and propagation to understand the behavior of materials under stress. Our crack growth analysis helps in developing maintenance schedules and improving design for enhanced durability.

Environmental Influence Assessment: Evaluate the impact of environmental factors such as temperature, humidity, and corrosive environments on material performance. Our assessments ensure that components can withstand harsh operating conditions.

Non-Destructive Testing (NDT): Utilize non-destructive testing techniques to inspect components for internal and surface defects without causing damage. Our NDT methods include ultrasonic testing, radiographic testing, and magnetic particle inspection.

Stress Concentration Reduction: Identify and address stress concentration areas to enhance the overall strength and fatigue resistance of components. Our solutions include design modifications and material selection recommendations.

Compliance and Certification: Ensure that components meet relevant aerospace regulations and standards. We provide comprehensive documentation and support for compliance and certification processes.

Customized Solutions: Deliver tailored stress analysis and fatigue testing solutions to meet the specific needs of your aerospace projects. Whether for new designs, upgrades, or maintenance, our solutions align with your goals.

Expert Consultation: Leverage the expertise of our stress analysis and fatigue testing engineers. We offer ongoing support and expert advice throughout your project lifecycle, ensuring successful implementation and operation.

Applications:

- Aircraft structures and components

- Engine parts and systems

- Aerospace tooling and fixtures

- Unmanned aerial vehicles (UAVs)

- Spacecraft and satellites

- Retrofit and upgrade programs

Why Choose Wings Of Aero?

Wings Of Aero is dedicated to advancing aerospace engineering through innovative and reliable solutions. Our “Stress Analysis and Fatigue Testing” service combines cutting-edge technology with deep industry knowledge to deliver components that meet and exceed performance expectations. Trust us to provide solutions that enhance reliability, safety, and longevity.

Contact Us:

Discover how our “Stress Analysis and Fatigue Testing” service can optimize your aerospace projects. Contact Wings Of Aero today for a consultation and take the first step towards engineering excellence.

Ensure the reliability, safety, and longevity of your aerospace components with Wings Of Aero’s “Stress Analysis and Fatigue Testing” service. Our comprehensive approach involves detailed stress analysis and rigorous fatigue testing to guarantee that materials and structures meet the highest standards of performance and durability.

Key Features:

Comprehensive Stress Analysis: Perform detailed stress analysis on aerospace components to identify areas of potential failure and ensure structural integrity. Our analysis includes finite element analysis (FEA), stress concentration factors, and load distribution assessments.

Fatigue Life Prediction: Accurately predict the fatigue life of materials and components under cyclic loading conditions. Our fatigue life prediction models consider various factors such as stress levels, material properties, and environmental conditions.

Load Testing: Conduct extensive load testing to evaluate how components perform under different types of loading conditions, including static, dynamic, and impact loads. Our tests ensure that materials can withstand operational stresses.

Cyclic Loading Tests: Implement cyclic loading tests to simulate real-world operating conditions. Our tests help determine the endurance limit and fatigue strength of materials and components.

Crack Growth Analysis: Analyze crack initiation and propagation to understand the behavior of materials under stress. Our crack growth analysis helps in developing maintenance schedules and improving design for enhanced durability.

Environmental Influence Assessment: Evaluate the impact of environmental factors such as temperature, humidity, and corrosive environments on material performance. Our assessments ensure that components can withstand harsh operating conditions.

Non-Destructive Testing (NDT): Utilize non-destructive testing techniques to inspect components for internal and surface defects without causing damage. Our NDT methods include ultrasonic testing, radiographic testing, and magnetic particle inspection.

Stress Concentration Reduction: Identify and address stress concentration areas to enhance the overall strength and fatigue resistance of components. Our solutions include design modifications and material selection recommendations.

Compliance and Certification: Ensure that components meet relevant aerospace regulations and standards. We provide comprehensive documentation and support for compliance and certification processes.

Customized Solutions: Deliver tailored stress analysis and fatigue testing solutions to meet the specific needs of your aerospace projects. Whether for new designs, upgrades, or maintenance, our solutions align with your goals.

Expert Consultation: Leverage the expertise of our stress analysis and fatigue testing engineers. We offer ongoing support and expert advice throughout your project lifecycle, ensuring successful implementation and operation.

Applications:

- Aircraft structures and components

- Engine parts and systems

- Aerospace tooling and fixtures

- Unmanned aerial vehicles (UAVs)

- Spacecraft and satellites

- Retrofit and upgrade programs

Why Choose Wings Of Aero?

Wings Of Aero is dedicated to advancing aerospace engineering through innovative and reliable solutions. Our “Stress Analysis and Fatigue Testing” service combines cutting-edge technology with deep industry knowledge to deliver components that meet and exceed performance expectations. Trust us to provide solutions that enhance reliability, safety, and longevity.

Contact Us:

Discover how our “Stress Analysis and Fatigue Testing” service can optimize your aerospace projects. Contact Wings Of Aero today for a consultation and take the first step towards engineering excellence.

Ensure the reliability, safety, and longevity of your aerospace components with Wings Of Aero’s “Stress Analysis and Fatigue Testing” service. Our comprehensive approach involves detailed stress analysis and rigorous fatigue testing to guarantee that materials and structures meet the highest standards of performance and durability.

Key Features:

Comprehensive Stress Analysis: Perform detailed stress analysis on aerospace components to identify areas of potential failure and ensure structural integrity. Our analysis includes finite element analysis (FEA), stress concentration factors, and load distribution assessments.

Fatigue Life Prediction: Accurately predict the fatigue life of materials and components under cyclic loading conditions. Our fatigue life prediction models consider various factors such as stress levels, material properties, and environmental conditions.

Load Testing: Conduct extensive load testing to evaluate how components perform under different types of loading conditions, including static, dynamic, and impact loads. Our tests ensure that materials can withstand operational stresses.

Cyclic Loading Tests: Implement cyclic loading tests to simulate real-world operating conditions. Our tests help determine the endurance limit and fatigue strength of materials and components.

Crack Growth Analysis: Analyze crack initiation and propagation to understand the behavior of materials under stress. Our crack growth analysis helps in developing maintenance schedules and improving design for enhanced durability.

Environmental Influence Assessment: Evaluate the impact of environmental factors such as temperature, humidity, and corrosive environments on material performance. Our assessments ensure that components can withstand harsh operating conditions.

Non-Destructive Testing (NDT): Utilize non-destructive testing techniques to inspect components for internal and surface defects without causing damage. Our NDT methods include ultrasonic testing, radiographic testing, and magnetic particle inspection.

Stress Concentration Reduction: Identify and address stress concentration areas to enhance the overall strength and fatigue resistance of components. Our solutions include design modifications and material selection recommendations.

Compliance and Certification: Ensure that components meet relevant aerospace regulations and standards. We provide comprehensive documentation and support for compliance and certification processes.

Customized Solutions: Deliver tailored stress analysis and fatigue testing solutions to meet the specific needs of your aerospace projects. Whether for new designs, upgrades, or maintenance, our solutions align with your goals.

Expert Consultation: Leverage the expertise of our stress analysis and fatigue testing engineers. We offer ongoing support and expert advice throughout your project lifecycle, ensuring successful implementation and operation.

Applications:

- Aircraft structures and components

- Engine parts and systems

- Aerospace tooling and fixtures

- Unmanned aerial vehicles (UAVs)

- Spacecraft and satellites

- Retrofit and upgrade programs

Why Choose Wings Of Aero?

Wings Of Aero is dedicated to advancing aerospace engineering through innovative and reliable solutions. Our “Stress Analysis and Fatigue Testing” service combines cutting-edge technology with deep industry knowledge to deliver components that meet and exceed performance expectations. Trust us to provide solutions that enhance reliability, safety, and longevity.

Contact Us:

Discover how our “Stress Analysis and Fatigue Testing” service can optimize your aerospace projects. Contact Wings Of Aero today for a consultation and take the first step towards engineering excellence.

Reviews

There are no reviews yet.