Wings of Aero, an aerospace startup, can provide assistance in creating prototype models using composite materials. Here’s how they can help

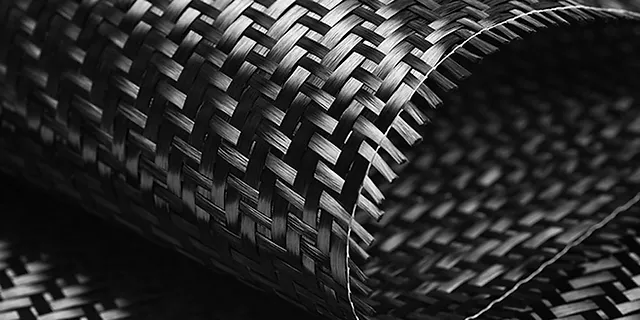

Expertise in Composite Materials

Wings of Aero has a team of experts who specialize in composite materials for aerospace applications. They possess in-depth knowledge of various composite materials, such as carbon fiber, fiberglass, and Kevlar, along with their properties, manufacturing processes, and performance characteristics. Their expertise enables them to guide you in selecting the most suitable composite material for your prototype based on factors like strength, weight, and cost.

Design Optimization for Composites

Composite materials offer unique advantages in aerospace, such as high strength-to-weight ratio and design flexibility. Wings of Aero can collaborate with you to optimize your design specifically for composite manufacturing. They can provide recommendations on design modifications to fully leverage the benefits of composite materials, ensuring that your prototype is lightweight, structurally sound, and meets the required specifications.

Composite Manufacturing Processes

Wings of Aero has knowledge and experience in various composite manufacturing processes, such as hand layup, resin infusion, and filament winding. They can determine the most appropriate manufacturing method for your prototype, considering factors like complexity, cost, and production volume. Their expertise in composite manufacturing ensures that the prototype is produced efficiently and accurately.

Tooling and Molding

Wings of Aero can assist you in creating tooling and molds required for composite manufacturing. They can design and fabricate molds or utilize digital techniques like 3D printing or CNC machining to produce precise tooling. By ensuring high-quality tooling, Wings of Aero helps in achieving accurate and repeatable composite parts.

Prototype Fabrication and Assembly

Once the design and manufacturing processes are finalized, Wings of Aero can fabricate the composite prototype parts using the chosen method. They have the necessary equipment and facilities to handle composite materials and ensure proper curing or bonding processes. They can also handle the assembly of the prototype, integrating various components and ensuring proper fit and functionality.

Testing and Validation

Wings of Aero can conduct testing and validation procedures on the composite prototype to assess its performance and verify that it meets the required standards. This may include structural testing, mechanical testing, or other specific tests based on your prototype’s application. The results of these tests help identify any necessary design modifications or improvements.

By leveraging their expertise in composite materials, manufacturing processes, and testing, Wings of Aero can assist you in successfully creating a prototype model using composites. Their knowledge and capabilities can ensure that your prototype meets the desired performance requirements while taking advantage of the benefits offered by composite materials.